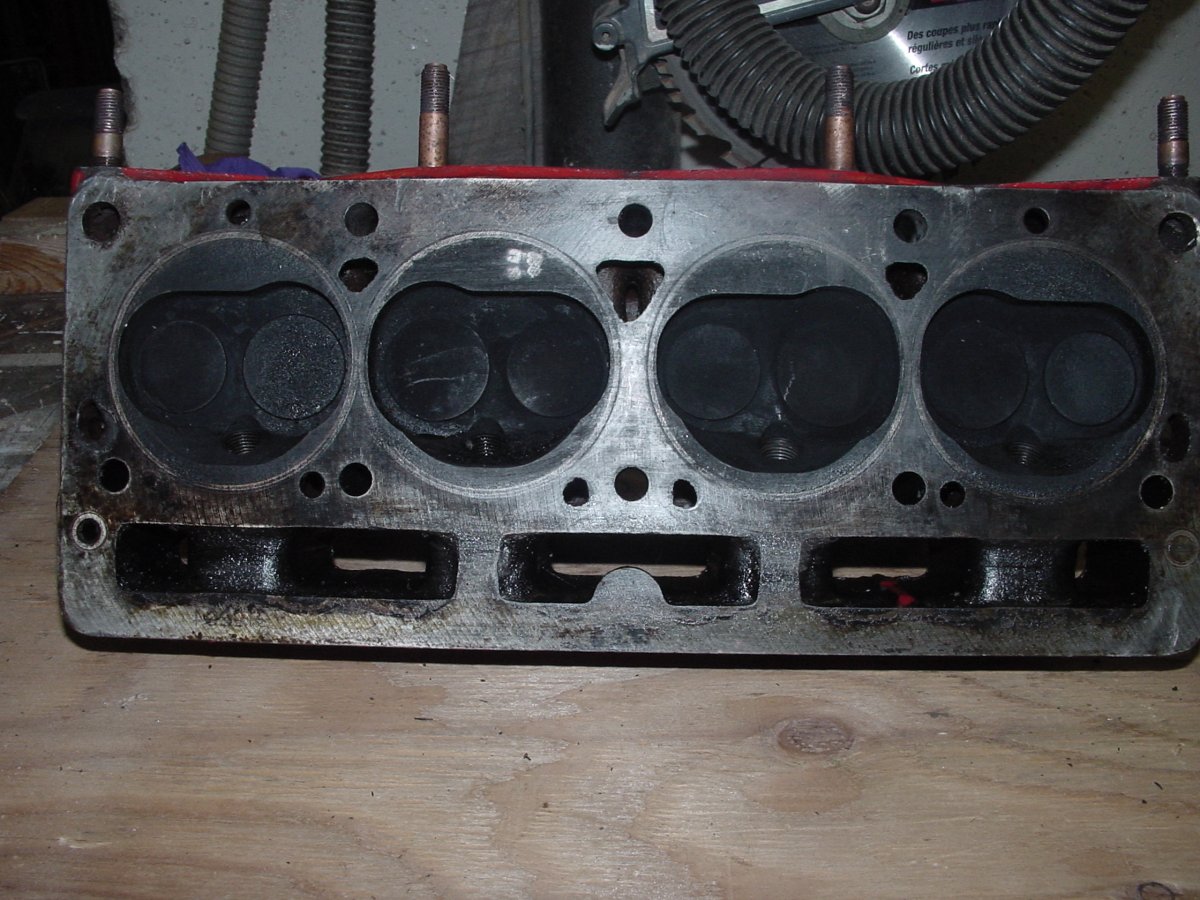

| Measurement Location | Cylinder #1 | Cylinder #2 | Cylinder #3 | Cylinder #4 |

| A Bottom | 2.901 | 2.900 | 2.900 | 2.899 |

| B Bottom | 2.900 | 2.900 | 2.900 | 2.901 |

| C Middle | 2.900 | 2.901 | 2.8995 | 2.900 |

| D Middle | 2.901 | 2.901 | 2.900 | 2.901 |

| E Top | 2.901 | 2.9025 | 2.9015 | 2.901 |

| F Top | 2.901 | 2.903 | 2.9015 | 2.901 |