1971 Triumph Spitfire Rebuild.

1971 Triumph Spitfire Rebuild.

This discussion is primarily directed at panel or dash illumination and

retrofitting LED devices to original incandescent design. We will not attempt to

cover microprocessor based or bus architecture control systems. (This is a

Triumph Spitfire.......)

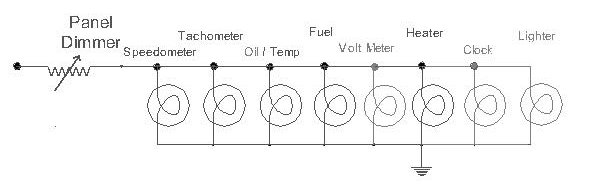

Most automobiles up until about perhaps sometime in the 1990's were fitted with a simple

variable resistor, sometimes called a rheostat to control panel illumination.

This was pretty straight forward. One had a known quantity of bulbs at a certain

resistance, that together would cause a predictable amount of current

to be drawn. An incandescent bulb exhibits a relatively linear light

output over a fairly wide input voltage. So simply, the light output is about

half when the voltage is half, so the

variable resistor was all that was needed. However if one or two lamps burned

out, the adjustment range broadened and the circuit did not work well. One for

the most part

could apply Ohms Law to determine the circuit characteristics.

The fact of the matter is that this is a bit of an oversimplification. Lamp resistance changes as the filament temperature changes, but so as not to make this rocket science.... I'll go with it

A LED on the other hand, although exhibiting a relatively linear output does

so in a very narrow range. First unlike a bulb, which is a resistive

device, the diode needs to overcome the forward

threshold and start to conduct before it begins to function. So in a sense the

LED goes from an off to an on state at some point. It is a very dim on condition

but on nevertheless.

The graph below depicts the relatively linear incandescent curve as opposed

to the fast rising current curve of the LED.

Another issued faced with retrofitting LED technology to older circuits is

the usual necessity of having to keep some of the original incandescent

lighting. One of the immediate

problems is the brightness of the bulb versus the LED.

If we consider a typical replacement bulb for the Spitfire it might be a 1487

or a 1815 bulb, depending if it is screw or bayonet base. The original bulbs

were a 2 watt version, these are a 2.8 watt version.

In any event, the bulbs light output is almost spherical, that is it glows

equally in all directions, except for the dead spot at the base. So

the rating given to them

is MSCP, or Mean Spherical Candle Power, or the light in all directions. In this

case the MSCP for these bulbs is 1.4

LED's are usually rated in mcd or millicandella.

To actually compare, we need a unit of measurement common to both. That would be the Lumen or the actual light output.

To convert MCD, milli candela to candela divide by 1000. So my 25000

mcd LED is really 25 candela, but at 15 degrees

beam width. ( By the way this is a really, really bright LED.) If you multiply

the candela by the degree beam width ( steradians), you can get the lumens

but first you need the steradians.

(Note: If doing this calculation in Excel, be sure to convert the COS function from radians to degrees.)

In this case 15 degrees is .2137 steradians X 25 Candela = 5.34

Lumen. To obtain the spherical value to compare to

the light bulb, divide 5.34 lumen by 4 PI or 12.56 = .425 MSCP. This is not

quite the 1.4 MSCP rating of the bulb.

There is however still one other problem, if you call it that. The LED, even

if you do the math and make the comparison is still in this case a 15

degree device. We can not change that. But this does show that even though the

LED uses less power and seems brighter it really is simply

the lens in the LED that makes it appear brighter.

The bulb at full brightness is 2.8 watts of consumption. The LED is .28 watts

of consumption at the same voltage using a single LED and current limiting

resistor. So that's approximately 1/10th the power for 1/3 the equivalent

lumens. But a lot of the power expended in the bulb is heat. It is

estimated

that incandescent bulbs 5 watts and under are around .5 to .7 % luminous

efficiency, while an LED can be 10 to 22 %. It is this writers belief

that these numbers may be skewed by the move to ban incandescent bulbs for

general lighting.

Back to the problem at hand.

This is a typical panel dimmer circuit for the Spitfire. Some components are optional..

If all bulbs are the original 2 watt style, the total current would be

approximately 1.3 amps. Using that, the calculated resistance of the lamps would

be

about 9 ohms. So using ohms law calculations, if the panel dimmer were set

to maximum resistance, around 24 ohms, the voltage drop would be

9.12 volts across the resistor and 3.48 volts across the bulbs.

If one changes these bulbs to the newer 2.8 watt versions to try to brighten

the gauges, the total power increases from 16 to 22.4 watts. Or 1.8

amps total light current. When the dimmer is in the maximum dim position,

24 ohms, the calculated current only increases slightly and the voltage drop

across

the resistor is now 9.24 volts or 3.55 watts dissipation.

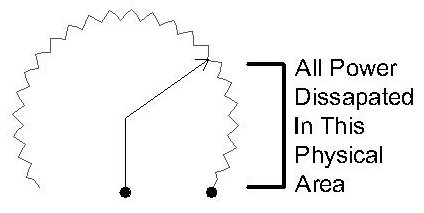

However the dimmer is usually not in the lowest position. It is typically all

the way up, negating its purpose, or it is about 75%

the way up. In this case the resistor is dissipating about 6 watts of power, but

it is doing it in 25 % of the controls physical structure.

So if we are looking at backlighting a gauge that requires a diffuse light, a

single LED

is typically not the answer.

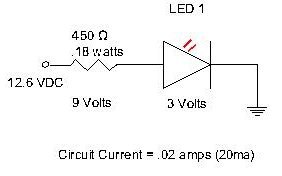

This is the typical single LED with dropping resistor circuit. The LED's I am

using have a forward voltage drop

of very close to 3 volts. Other LED's will vary . I am also using the

specification of 20 milliamperes. Some LED's are specified

at 30 ma. The current specified for the device can vary. I've run LED's up

to 200 ma in test. At some point they can actually change color,

and even dim as current increases. This is slightly before they become an FED, a

Flame Emitting Diode.

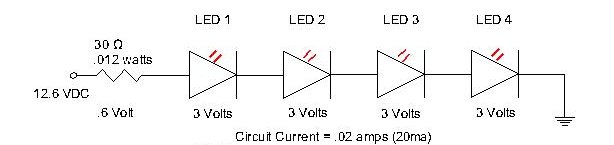

Another variation, and one that I'll be using in the speedometer and have

currently designed into the tachometer conversion

is 4 LEDs in series. The advantage is that only .012 watts of power need to be

compensated for as the LED's drop most of

the 12 volts. This also has an advantage in a larger gauge as they are

positioned at the 12, 3, 6, and 9 o clock positions and facing to the front

of the gauge. This is opposed to the single point light source relying on diffusion

of a plastic piece and reflection from the inside of the gauge.

(This is an internal gauge modification.) The LED locations are at

the red circles on the perimeter of the circuit board. The circle in the upper

part of the board

is the cut out for the stock incandescent bulb if desired.

Tachometer Circuit Board

Showing LED Placement

In this case the LED directivity can be used to its advantage. The

LED faces forward and is reflected off the painted gauge housing and the rear of

the

tachometer face to provide a diffuse lighting pattern.

This circuit will dim quite nicely and linearly, however it does it all within

about a 1 1/2 volt range. The LEDs are off at 9.2 volts, trigger on at 10

volts,

and achieve full brightness at 12.6 volts. Not all LED's have this same

characteristic which complicates the issue.

The Spitfire panel dimmer, if fitted, is a variable resistor with a range of

about 1 to 24 ohms. If we use E=I*R

we can see that the voltage drop across this at 24 ohms is .48 volts. However as

the LED is not a resistive device,

all we are doing at this point is varying the amount of heat dissipated by the

resistor. This is because at this point

the LED's are still conducting at a fairly constant 20 milliamperes, and we have

not got down to the theoretical

12 volts where we can affect the current.

We can add light bulbs to increase the current thus the voltage drop across

the dimmer, however due to the very different

characteristics of the devices, they do not dim equally. And, if we are going to

add bulbs to try to solve the problem,

why bother with LEDs at all?

A typical Spitfire panel dimmer.

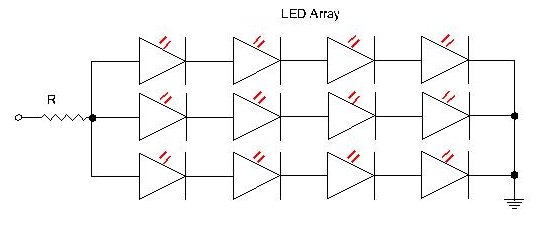

The following is a schematic representation of a typical LED

array used in replacement bulb technology. The

number of LED gangs may be more or less. Many, but not all of these on the

market use a single current limiting resistor

as depicted in the schematic. It all depends on the chip style LED that is used

and the mechanical configuration.

The most practical way to reliably dim both LED's and / or

incandescent bulbs is by varying the duty cycle that the devices are on versus

off.

This is also known a Pulse Width Control. The following graph illustrates the

concept. At 50 % duty cycle the LED is on the same amount of time it is off

resulting in about half relative brightness. Similarly, at 90% duty cycle,

or on 90% of the time the LED is at nearly full brightness and conversly at

10% duty cycle the LED is off 90% of the time and therefore very dim. This

happens at a fairly high frequency. In my circuit it is approximately 250 hZ

I've built a

solid

state dimmer module. It uses a simple timer chip as a pulse width modulator

to vary the time the LEDs and or bulbs are on as opposed to the time they are

off. It does not matter if it is LED's

or incandescent bulbs or a combination.

This does not effect the life of the bulb or LED.

This does

require rewiring the circuit as the bulbs are switched to negative ground. This means that you supply 12 volts to one side of

all the

illumination bulbs and / or LED's and the return to ground or car chassis goes

through the module. I've built it both ways, ie the type

that requires no wiring modifications. For my purposes, this design works

best, but does require the wiring modification that probably very few

would want to tackle. One of the reasons I'm using this configuration is to

minimize electrical noise as the car will contain some communications equipment.

As I'm rewiring the entire car anyway, this is no big

deal. This does require changing some of the illumination sockets to

ones that do not electrically connect to the gauge housing. In the case of the

speedo, one needs to provide another way of grounding as the gauge regulator

gets its negative side as part of the housing through the original lamp socket

ground. The regulator has been converted to solid state as well. However

in my

application it is not needed as the only gauge needing regulation is the fuel

gauge and that is built into it. And as I plan an internal lighting circuit

board, this is probably a non issue.

I have found that stock lamp holder for the ignition switch

illumination is

perfect for this. Victoria British sells a version, however I do not know

if it is case isolated or not. Their

part # is 14-971, but again, not sure if this is isolated. I had enough

sockets between everything to do what I need so I've not ordered any.

On the back of the module are the connections and a power transistor on a

small heat sink. This generates no measurable heat even with over 4 amps

of current.

The switching transistor

is good for 12 amps but we rate it at 4 maximum. If it fails it should

fail with bulbs on full brightness.

The switch on the pot is to control courtesy lighting manually, something Spitfires never had.

It looks like this:

This lamp is actually at half brightness. LEDs work the same on this as the lamp does.

Plug and Play Dimmer Unit

A solid state replacement for the Spitfire Panel Dimmer can be

found at the following web site that advertises an Over Drive

Controller.

Look for the link for Dashlight Dimmer Retrofit. I have no affiliation nor have

any experience with this product or the company producing it.

I offer this for informational purposes only. I have e mailed the owner and have

been given permission to post this.

This looks like a very nice solution at a very reasonable price.

http://od_cntl.webring.com/Overdrive_Controller.shtml

Or e mail: od_cntl@hotmail.com

Ohms Law chart for your reference.

When you've let the smoke out....., Get This